Premium GI Wire Manufacturer in Akola

What is GI Wire or Galvanized Iron Wire?

The GI Wire (also known as galvanized iron wire) is one kind of wire made of iron which has been subjected to a galvanization process. The process of galvanization involves coating of zinc on the wire surface in order to make a galvanized wire. This zinc coating process is carried out in conjunction with other steps like the annealing process and tempering.

Manufacturing of GI wire is a process that involves a range of steps like tempering, annealing welding, picking, polishing and packaging. The continuous wire is dipped into a molten bath that contains zinc at temperatures that range between 200 and 400 degrees Celsius based on the thickness of the wire. After dips, the wire will be cooling down under controlled conditions. Post-dipping treatment includes annealing, temperting and pickling.

Galvanized Iron Wire has a metallic grey finish on its surface that offers advantages like durability, corrosion resistance and protection against rust, enhanced endurance, tensile strength and strength. Mechanical properties of gi wire are similar to mild steel but they exhibit superior corrosion resistance. Additionally, it has better flexibility than mild steel.

Premium GI Wire Manufacturer in Akola

Systematic Group, established in the year 2000, with a capacity of 300 MT per month is now the premium galvanized wire manufacturer or gi wire manufacturer in Akola.

We specialize in designing and manufacturing a variety of high quality galvanized wires, hot-dipped galvanized wires chain link fences and wire mesh according to the desired finish, using top quality raw material i.e. wire rod.

Our company offers galvanized steel wire with the highest quality for various applications like industrial, commercial, construction sectors, as well as marine.

With the advancement of technology, and the development of sophisticated manufacturing facilities our annual capacity is more than of 100,000 MT. This proves that we are leading across the globe. In addition, pan-India distribution is another initiative, which has helped us to expand our reach and build more supply chains all over the world.

We are devoted to our customers so providing them with the best possible service is our responsibility. We’re known for our seamless workmanship that has made us stand out amongst our competitors. We deliver our products in accordance with the needs of our clients and on time which showcases our professionalism, which is an essential quality when it comes to working as an entire team.

Our spirit is always high in the workplace and we all understand the importance of their role. If you’re looking for the top Gi wire producer at reasonable prices in your city then you should look into the services provided through Systematic Group.

How is GI Wire graded?

There are a variety of kinds of categories to consider when classifying the thickness of GI Wire or Galvanized Iron Wire. These categories are determined by the diameter of the wires which are used in the production of GI Wire or Galvanized Iron Wire and the number of wires which can be wound together to produce a certain thickness, thus creating a specific gauge.

A gauge is basically the standard measured by which it could be determined how thick or thin a particular wire is, such as a 100-gauge wire or a 50-gauge wire. The larger the gauge number, the thinner the wire is. There are many different gauges. A few examples of these gauges are 18-gauge, 16-gauge, 12-gauge, and 10-gauge.

A wire diameter is measured in millimeters. There are many different sizes of wire diameter. Usually, the larger the diameter, the thicker the wire is, and vice versa.

GI Wire Price in Akola

The gi wire price varies depending on the grade and size of wire. Standard GI wire is available in standard sizes like 2.5 mm gi wire, 3mm gi sheet, 4 mm gi wire and different gi wire gauge like 6 swg gi wire, 8 swg gi wire, gi wire 10 gauge, gi wire 10 swg, gi wire 12 gauge. If you are looking for gi wire price per kg or gi wire rate today , gi wire 12 gauge price, gi wire 10 gauge price, gi wire 4mm price etc you should get in touch with our executive to get the best gi wire at affordable prices.

Our Galvanized Wires sales and distribution network in Akola

We identify ourselves as the top supplier of G.I. wires in Akola. Our customers in Akola range from large OEMs, traders, distributors, and exporters; our service network of highly dedicated sales and technical people ensures our leading position for preferred Galvanized wire suppliers in Akola.

We are one of the few galvanized wire manufacturers who have a field presence in Akola. With our focus and customer-centric attitude, we are able to provide

Our GI Wire Product Range in Akola :

- Best Galvanized Wire (GI wire), G.I. Wires price in Akola

- Hot Dip G.I Wire, Hot Dip Galvanized Iron Wire, Hot Dip GI Wire in Akola

- Barbed Wire, Barbed Galvanized Iron Wire in Akola

- Top supplier of hb wire in Akola

- Top-manufacturing of galvanized binding wire in Akola

- Top Wire Mesh (wire jali) , Construction wire mesh, Barbecue Wire mesh manufacturers and supplier in Akola

- Galvanized wire: hot-dipped Galvanized wire, wire for Gabions, and wire for agriculture and fencing wire

- Chain Link Fence Galvanized Iron wire, Chain Wire.

- Wires for Power Industry: round and flat cable Armour wire, galvanized steel tape

- High carbon and low carbon steel wires: Spring steel wire, cold headed quality (CHQ) wire, fine wire for steel fibers, Rope wire, conveyor belt wire, annealed wire, pre-stressed concrete (PC) wire, and, binding wire, flat wire, low-carbon iron wire

- Wire and wire Products: welded wire mesh, CO2/MIG welding wire, stay wire, shaped/profile Wire, and circlip wires, wire fibers

- GI Stay Wire

Product Description & Product Specification:

Hot Dip Galvanizing Wire in Akola

- Diameter: 0.90 mm to 6.00 mm

- Zinc Coating:30 to 366 GSM

- Tensile Strength: 300 to 900 N/mm2 or 300 – 900 MPA

- Stadards: IS 280(1978), BS 443 (1982), BS 5467 (1997), BS 6622 (2007), BS 7846, ASTM A641/A641m (1998) Class A, IS G3547 (1993), AS 1650 (1989), AS 2423

- Packaging Type of Galvanized Wire: Rolls

- Price GI Wires: Available on Request

* Note: We can custom manufacture products as per your requirements.

Chain Link Fence in Akola

- Hot Dipped Galvanized Wire : IS 280 Wire

- Size: 1.6 mm,2 mm, 2.5 mm,3 mm ,4 mm 16 gauge, 14 gauge, 12 gauge, 10 gauge, 8 gauge

- Width / Height: 3 Feet to 10 Feet

- Length: 15mtr, 25mtr, 30mtr

- Zinc Coating on wire : 60gsm to 300gsm

- Mesh Size: 1” to 4” 25mm to 100mm

- Packing Type: Compact

Wire for Fencing in Akola

- Diameter : 2.00 mm – 4.00 mm

- Zinc Coating: 30 – 300 g / m2

- Standards IS 280 (1978), BS 10223 Part3

- Price Product Details: Available on Request

Wire for Farming in Akola

- Diameter: 1.4 – 4.0mm

- Zinc Coating: 30 – 300 g / m2

- Standards IS 280 (1978), BS 10223 Part3

- Price Product Details: Available on Request

Wire for Poultry in Akola

- Diameter: 0.90 mm and above

- Zinc Coating: 90 – 300 g / m2

- Standards IS 280 (1978), BS 10223 Part3

- Price Product Details: Available on Request

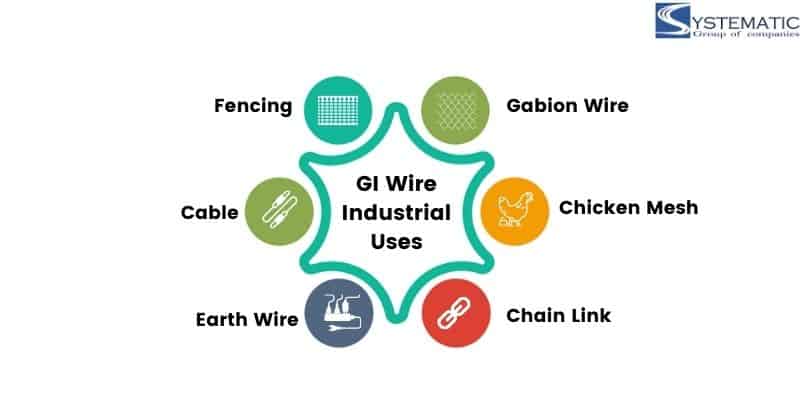

Galvanized Iron Wire Usage in Akola

Galvanized Iron Wire is used in various applications such as construction, electrical power transmission, mining, oil drilling, marine engineering, shipbuilding, and many more. It is also widely used in the agricultural sector for crop protection, irrigation, and livestock management. The most common use of galvanized iron wire is in fence posts, cattle grids, and other animal enclosures.