Types of Galvanizing: Why Hot-Dipped Galvanization is Best for Steel Wires

Types of Galvanizing: Why Hot-Dipped Galvanization is Best for Steel Wires

Posted on June 06, 2019Types of Galvanizing

As you know, galvanization is the process of protecting a metal article from corrosion by applying a thin layer of zinc coating on it. It is mostly used in the case of cast iron, ferrous alloys and steel wires, which are exposed to corrosion. In fact, galvanized steel wires find a variety of applications in our day-to-day lives, in building construction materials, outdoor fences, electric cables, steel ropes and more. However, there are three main types of galvanization process that you should have a concrete knowledge about. It will further ensure you make the right choice, when it comes to investing in galvanized steel wires.

The Different Types of Galvanizing Process

• Electrogalvanization – In this type of galvanizing process, the raw metal is submerged into an electrolyte solution, in which the anode is composed of zinc. As the process of electrolysis happens, current starts flowing into the metal from the zinc anode and particles of zinc get coated on its surface. However, this protection is both uneven and pretty thin but boasts a shiny appeal. Moreover, the process does not follow any rigid cleaning procedure of the raw metal before the electrolysis, which tends to impurities getting stuck on the surface of the metal.

• Hot-Dipped Galvanization – This procedure is preceded by a series of cleaning and rinsing steps to get rid of all impurities. The wire is first cleaned in a caustic solution to do away with scales and impurities, following which it is rinsed thoroughly, and a non-oxidized compound, or flux, is added to it. Thereafter, the wire is immersed in molten zinc at a temperature range of 443 – 465° Celsius, or 830 – 870° Fahrenheit. As the result of a chemical reaction between iron and zinc, a layer of pure zinc gets deposited on the surface of the wire, thus creating a protective layer on it. Although the hot-dipped galvanized steel wires are not as shiny as the eletrogalvanized ones, the coating is thicker and less impure. Guess all that shine are not really gold after all!

• Cold Galvanizing – Well, basically, this has less to do with galvanization and more with painting. It involves applying a resin-based zinc varnish on the steel wire to form the protective layer of coating. However, it is quite ineffective in terms of abrasion resistance and has the lowest service-life than the aforementioned types of galvanizing process. The term is used for marketing purposes basically; otherwise, cold galvanizing is all about painting the steel wires with zinc-enriched paint.

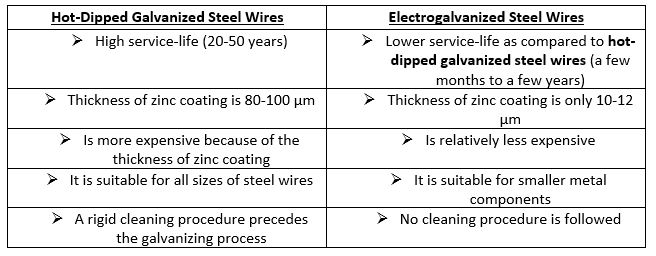

Now, if you are stuck between hot-dipped galvanized steel wires and electrogalvanized wires, check out the table below to note their basic differences:

The hot-dipped galvanized steel wires or GI wires manufactured by Systematic Ltd have zinc coating of 30-300 g/m2 and diameter of 1.40 mm or more. They can be used in building wire-mesh cages, outdoor fences, barbed wires, and may find several other farming and industrial applications. The SS wires also adhere to the standards of IS (280), BS 6622 (2007), ASTM A641/A641m (1998) Class A, and a lot more. You can get in touch with us through mail, or you can call us directly to discuss your specific requirements. We are always here to help you make the right choice, when it comes to the best quality steel wires.

Be the first to write a comment.

Leave a Reply

You must be logged in to post a comment.